There are a lot of other parts necessary for a reliable dosing skid like valves, filters, check valves, flexible hoses, dissolving baskets, level transmitters, pressure relief valves, pressure indicators, pressure retainer valve. Watcon will choose always the best quality price ratio and uses brands of parts that are easily serviceable around the globe.

As we constantly seek for improvements and encounter all kinds of specific process demands with our customers we have developed a lot of apparatus during the last 31 years. Please ask if you have a particular question.

Best White Hat SEO Expert In Bangladesh

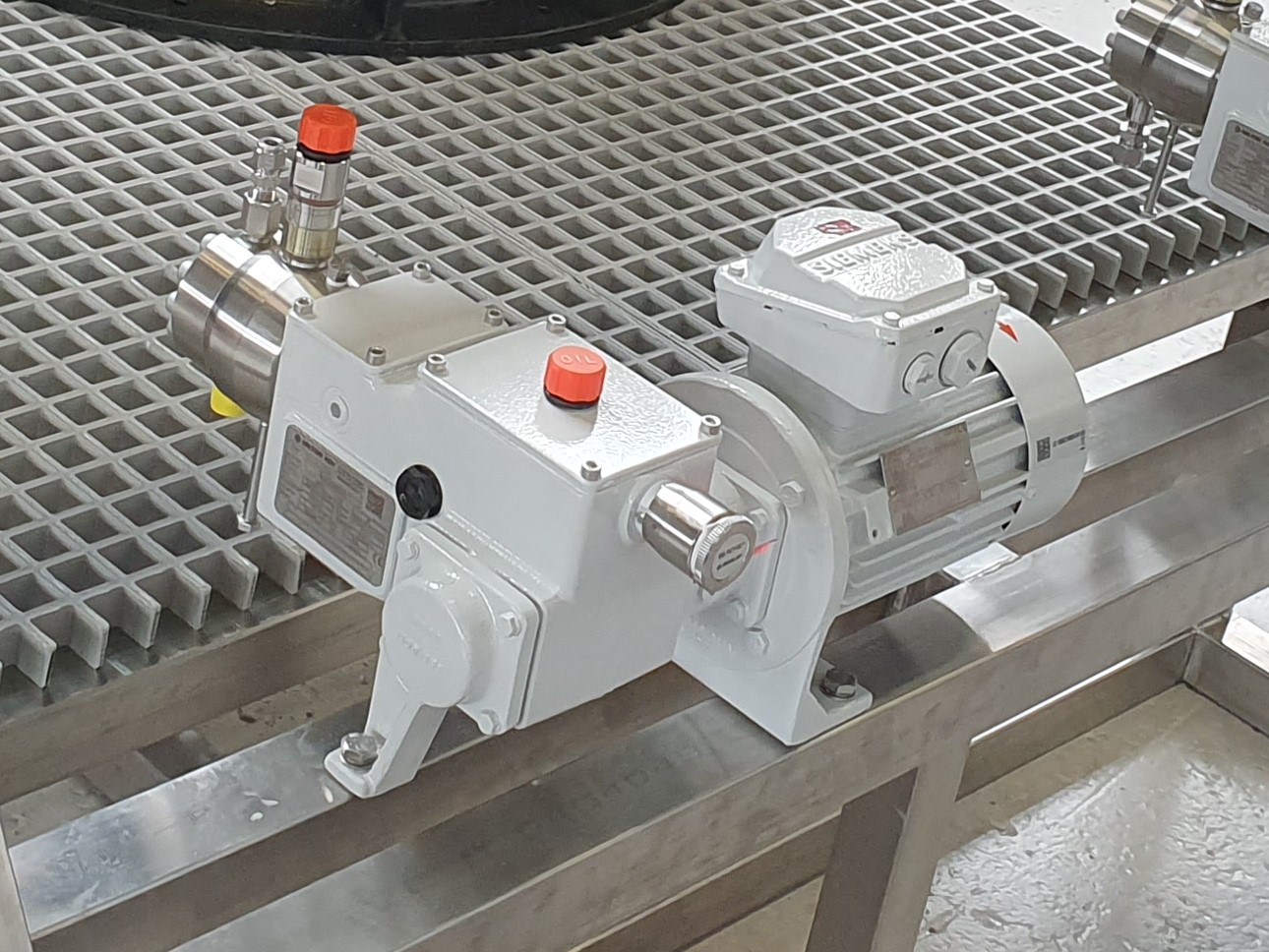

The (petro) chemical industry is a valued customer of Watcon, we have a large experience and knowledge of Ex. Equipment.

- All electrical cabinets and apparatus ATEX approved.

- Cabling and execution of cabling ATEX approved.

- Knowledge of brands of dosing pumps and other electrical equipment needed with Ex approval.

- All with full documentary approvals, NOBO certificats and test.

Oxygen scavengers like Carbo Hydrazide need to bind oxygen in the steam water circuit, when in contact with air it will lose its capacity to do so. Therefore isolation from air is needed.

Watcon has several methods to do so, please ask.

Vapour Lock with cartridges for absorption of hazardous and pollutant chemical vapors produced during the filling, decanting and draining of closed pressure less storage tanks.

- Pressure, Vacuum breaker

- Sizes suitable for the tank contents.

- Easy cartridge replacement.

- Absorption materials specific for the chemical.

Calibration columns provide a simple and effective method for determining pump flowrate using industry-standard graduations of milliliters/minute and/or gallons/hour. Please ask

- Sizes to fit your pump capacity

Pulsation dampers are used for stabilizing the flow and the pressure in the pulse line as the dosing pump acts with strokes (pulses) per minute. The damper consists of 2 chambers separated by a bladder, the opposite chamber is filled with pressurized Nitrogen, this pressure corresponding with the pump pressure. Please ask

- Size and nitrogen pressure to fit your application

- All stainless steel, bladders of suitable chemical resistant material available

- According to the European PED97/23/CE, design meets the AD-2000 and ASME VIII Div.1 & 8 codes

Chemical injection quills ensure that chemicals are evenly dispersed into the center of the pipeline, which prevents channeling of the chemical down the pipe wall. The quils are equipped with a removable check valve to prevent the medium (or boiler water) to flow back to the dosing tank and to give the necessary back pressure to the pump.

- Different back pressure values of check valves available

- NPT threaded connection.

- Stainless steel 316 or higher grade material.

Our electricians design electrical panels according all customer (company) codes and standards and local legislation. The functionality and operational interface is designed according our long experience and customer preferences.

- All according highest level of workmanship.

- Comprehensive test and check lists fulfilled.

- Plug and play unit, skid cabling included.

In and outdoor for all climates.

In and outdoor for all climates.- Suitable for Ex hazardous zones if applicable.

Watcon is an independent system integrator, we are free to choose the brand and type of dosing pump which is the best for your application in terms of quality and price. We have experience with all major brands and keep close relations with all, resulting in very good purchase conditions of which in turn our customers benefit. Please ask.

The quantities to be dosed are small, from 0,5 to 5 ltr/hr. a litle bit of chemical in ultrapure water (almost empty) has a big effect ! But the pressure to pump up against can be high (> 100bar) And the dosing lines can be long.

These conditions ask for special knowledge and experience when designing a dosing skid and choosing the right pump.

We only apply the most durable proven pumps, designed to go on forever, not being able to dose is out of the question. Please ask for a consult.

- Free to choose the best price/performance ratio

- Only high quality proven brands are selected

- API 675 compliant

- Meets specific requirements for Steam Water circuit.

Spares of pumps

The dosing pumps need maintenance and replacement of parts on a regular (yearly) basis to function well. We deliver spares all over the world, we know exactly which type of spare you need or have an alternative if obsolete.